Practical solutions for draining and drying different claddings

By Doug Horgan

DOWNLOAD THE PDF VERSION OF THIS ARTICLE. (2.82 MB)

What should be used behind the cladding on a house to protect against moisture? We know that a fully vented, wide drainage and drying space (what is often called a “rainscreen”) works well. But creating such a space can be expensive, and other, less expensive approaches often work, too.

As an industry, we’re in a period of transition and learning as we build walls with more insulation than in previous decades. However, we do know this: When we add insulation, the outside of a wall stays colder all winter. This results in less drying and more moisture in sheathing and claddings. Therefore—generally speaking—walls with more insulation need more consideration for drying than those with less. Whether a problem or failure results will depend on a list of factors, including climate, building shape and exposure, interior humidity conditions, even future maintenance—the wrong paint can cause issues, as can caulking drainage weeps closed. In this article, I’ll introduce how we address these factors when we decide how to detail different types of siding.

Climate Factors

Our company remodels dozens of houses a year from which we remove old siding, stucco, brick, or stone, so we have been able to see how wall assemblies fare in our climate around Washington, D.C. Winters here are milder than in northern states, and they tend to be wetter than in western states, so what works for us may not work for others. In colder areas, you will likely need more protection behind the siding than we use (though interestingly, areas with long, cold winters have fewer wood decay issues than places where it’s wet and warm for more of the year). And once you get into the high plains of the western U.S., there’s much less rain and, from what I have learned, nowhere near the same levels of protection are needed.

In the warmest, wettest parts of the U.S., vapor management to control summertime moisture conditions is often recommended on the outside of walls, too. It’s important to take local conditions into account.

Exposure

In the areas we work, houses are usually on land without tall hills and surrounded by other houses and trees, so exposures to wind and weather are not severe. However, when we do build on a hilltop or next to a large body of water, we need to use higher levels of moisture protection to withstand wind-blown rain and snow.

Insulation Levels

Why Impermeable Sidings Need Drain Spaces

Plastic-based siding materials don’t allow moisture through them, which can be great when they’re keeping rain out, but unlike traditional wood or even wood-product and fiber-cement sidings, they also don’t allow water that gets behind them to pass through and dry out before damaging the building.

My limited experience with impermeable sidings (mainly PVC “panel”–clad walls) is that they need significant drying space behind them compared with their wood analogs. Once water gets behind plastic sidings without drain and drying space, it can quickly cause serious problems.

We had lots of durability problems with panel designs made of wood trim and plywood panels, but they rarely affected the wall behind the WRB. I believe water that leaked in was absorbed into the wood boards. This kept the water from being absorbed into the wall assembly but usually rotted the wood trim, which is why we moved to plastic trim boards. —D.H.

Most of the buildings we have built or taken apart lack continuous insulation. In fact, most of them have just 2×4 walls with batt insulation between the studs. Now, with recent code updates, we’re building walls with half, or less, the energy flow to the exterior. These walls are not drying as quickly or as often as their predecessors did. Also, we are using a variety of materials on the outside of houses that we didn’t use in the past. Of note are the wide range of impermeable, plastic-based materials that are less prone to drying than the wood-based and fiber-cement materials we’re more accustomed to installing (see “Why Impermeable Sidings Need Drain Spaces” at right).

All our experience with past buildings and materials is different from what we face today. In some cases, we are only able to make educated guesses about what will work or fail in new walls. Nevertheless, we must adhere to the best principles we know, and toward this end, we created a chart (see chart “What Goes Behind the Siding?,” above) that identifies four different levels of protection behind the different sidings we install. These help us to clarify and simplify our options and retrain our crews and subcontractors, whose instincts may be based on experience.

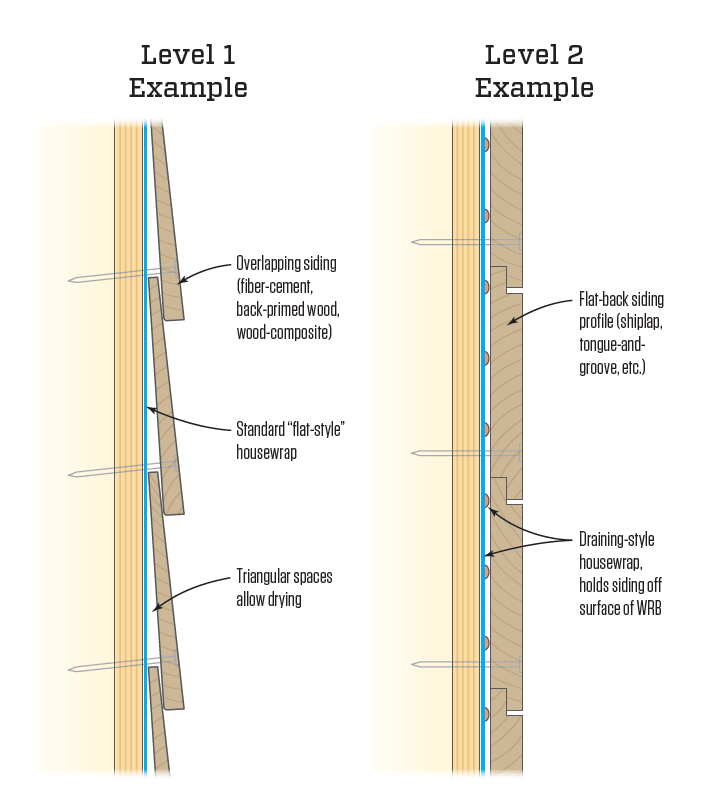

Level 1

In the chart’s first category are permeable siding materials with spaces behind each course and lots of joints and openings. Lap siding made of wood, fiber-cement, or wood-fiber composites all fit this category, as does standard vinyl or metal siding (with hollow-back profiles, not filled with foam). Based on our experience disassembling many houses built with these materials, we know they perform adequately in our climate even when installed over flat WRBs (those with no special draining provisions), so that’s our minimum requirement.

Two notes on this: Other provisions in our company’s standards require wood siding to be fully back-primed; this is important when plastic wraps—which will lose water repellency when raw wood tannins soak into them—are installed. Also, we note that highly insulated walls need more drying capacity than the “Level 1” requirement provides. We’ll often have a conversation with clients about paint durability, as well. Our experience (including on my own house) is that adding a drying space behind wood siding provides a tremendous boost in paint longevity. For a client planning to stay in their house for a long period, this upgrade is often worthwhile.

We don’t have much opportunity to install conventional vinyl siding in our market, but when we pull vinyl siding off walls, we see how it fared. It generally does well at protecting the wall when properly installed. This may not be true in other parts of the country and in homes with significant indoor humidity loads that dry to the outside. George Tsongas’ experience in the Pacific Northwest and on multifamily buildings suggests the need for a greater level of treatment than the usual Level 1 treatment that we can safely employ around here (see “Installing PVC-Type Sidings in Cold Climates,” by George Tsongas, Jul-Aug/22).

Level 2

The second level for siding protection uses a “draining” housewrap to provide a small drain cavity (a couple examples of these “bumpy” wraps are shown in the photos above). These products typically have a 1/16‑inch gap for water and air to move through, offering much more drainage than a flat WRB, but they still retain some water due to water’s surface tension. Though a 1/16‑inch gap isn’t wide enough to offer much drying capacity, it’s more than a flat wrap provides.

We use draining WRB materials for permeable sidings like wood and fiber cement, which have a flat back surface; the bumpy wraps keep water from seeping through the WRB, which can happen when water is trapped against it (for more about this, see “Water Managed Wall Systems,” by Joe Lstiburek, Mar/03).

Level 3

The third level replaces the 1/16-inch bumps on “draining” housewrap with a wider, 3/16- to 1/4-inch drain space. To create this space behind siding, we almost always use drain-mesh products since they’re commonly used around here. They have the advantage of allowing horizontal, along with vertical, drying and air movement. (For more, see “Increasing the Effectiveness of Drainage Spaces.”) We sometimes use other materials, as well, including strips of 1/4-inch fanfold insulation, corrugated plastic, or sill seal foam.

We call out this level for several risky claddings, including solid, plastic-based sidings like cellular PVC, “poly-ash,” and the new rice-hull-PVC product. These materials don’t allow any moisture through at all, so we have to make a clear path for it to dry out from behind.

We also call out this enhanced protection for “panel” designs (see illustration, below). In addition to the panels having a flat back and limited drying through their materials, they tend to leak at joints near the rails, which trap water. Cedar shingleswith their multiple layers, which also tend to hold water, benefit from this level of protection, as well.

Level 4

The fourth level of protection adds a second layer of WRB material for redundancy and code compliance. Claddings in this category—including stucco, adhered stone and manufactured stone, brick veneer, and stone veneer—hold rainwater, and when the sun hits the cladding, that moisture is driven into the wall. In our climate, one of the WRB layers should have low permeability; for instance, felt or one of the coated OSB sheathing materials, such as Zip System.

Siding over Exterior Insulation

Layers of insulation outside a structural wall help shut down thermal bridging, which is why that approach appeals to many. But it can add complexities to water and moisture management.

There is a bright side on the moisture front: If the insulation is thick enough and the structural sheathing is kept warm enough in cold months, the risk of interior moisture accumulating in the sheathing is sharply reduced or eliminated. This can allow use of more permeable interior vapor management (latex paint, for example, rather than a complicated layer of sealed, 6-mil plastic), which can be easier to apply and less expensive and enable walls to dry better toward the interior.

However, we must address two potential downsides to continuous insulation: First, many insulation products are moisture resistant and, if they are tight to the sheathing/WRB and water gets behind them, it’s likely to stay there long enough to cause damage. Second, some insulation materials can absorb or hold water, which prolongs drying even more.

The two most common approaches that address the first issue are to take steps to prevent water entry and to provide a small drainage space behind the insulation.

Arguably, the best way to keep water out is to properly install a WRB in front of the insulation, though this can be challenging to detail at windows. Some insulations have tongue-and-groove joints, which can be oriented with the tongue up to shed water. Taping joints and/or using a Z-flashing can also cut the chances of leaks (though preferably not a metal Z-flashing, which can create a thermal bridge). But our imperfect buildings are built by imperfect people, and it’s asking a lot for every square inch of insulation to be installed perfectly. Creating a way for water to leave is the preferred strategy.

As for the second approach, we don’t want a huge space behind the insulation for air to blow around, or the insulation value will be compromised (an effect sometimes called “wind washing”). What is the right space? There’s a tug of war between optimal drainage and optimal protection from wind washing. For example, we commonly use 3/16-inch drain mesh behind EIFS (see “Three Ways to Install Drainable EIFS Wrong (and One Way to Make It Work),” Nov-Dec/22), which I believe is the minimum needed for reliable drainage and drying for a waterproof, sealed cladding with no other drying gap. However, this size gap is known to cut the insulation value of the exterior insulation. A 1/16-inch gap is often suggested to minimize wind washing, but this offers minimal drying and can hold water due to surface tension. We’ll learn more in decades to come as we try various new approaches and find out which ones work reliably.

Meanwhile, we already know some things:

Mineral board (rigid fiberglass or rock wool) is very permeable and will permit drying directly through it. As long as there’s a drying space between it and the cladding, it seems safe to place this type of insulation directly on the sheathing/WRB.

Expanded polystyrene (EPS) foam is somewhat permeable and provides some drying, though less as its thickness increases. I would install a drain gap behind EPS to be safe.

Extruded polystyrene (XPS and faced polyiso insulation boards) are nearly impermeable and should be treated with care. Any water that gets between them and the sheathing will likely cause problems unless a drain space is provided. On the other hand, their nearly waterproof properties mean they can be detailed to block water from getting further into the assembly.

Wood-fiber insulation board is a material I haven’t installed or even seen installed in my area. In theory, it’s permeable, so it should allow drying, and the absorbent wood fibers should help transport water away from a particular leak spot. Of course, wood fiber is susceptible to damage from repeated wetting—though the wood fiber is reportedly treated with paraffin wax as water protection and with borates to resist mold, rot and insects. It will be interesting to see how this insulation performs long-term.

Photos by Doug Horgan; Illustrations by Tim Healey.

Keep the conversation going—sign up to our newsletter for exclusive content and updates. Sign up for free.

About the Author

Doug Horgan is vice president of best practices at BOWA, a design/build remodeling company in McLean and Middleburg Va.